Search Results for: DRIVER_IRQL_NOT_LESS_OR_EQUAL (d1) rtux64w10

-

Pallet Return & Stack Devices

3rd March, 2017 | by excitemediaAvoid injury risks anywhere in your facility. Pallet Return Devices will assist production workers with the hard labour task of stacking empty wooden or plastic pallets without using an outside energy source such as electricity or compressed air. They are the perfect pallet return solution that many operations, specifically distribution centres, general warehousing facilities, manufacturing facilities, food and beverage plants, and retail stores, can benefit from. It works to increase the safety of your facility by reducing the risks of handling pallets with a lifting method that reduces musculoskeletal disorders. The units also reduce the risks of falling pallets because a ‘perfect’ stack is less prone to tipping over and causing a potentially serious injury. A neat stack also reduces labour costs as labourers no longer have to struggle to make an acceptable stack and fork truck drivers avoid reshaping a stack of pallets when ready to be handled again. An optional flashing strobe alerts forklift driver a full stack is ready for pickup.

Pallet Return Devices are available in two configurations: Stand Alone Floor Configuration & Pick module.

Stand Alone Floor Configuration can be mounted in any facility with a flat surface so the benefits experienced in a pick module can also be experienced in all other areas of a facility. Anywhere that pallets are stacked, the stand alone floor model can be there to assist!

Pick Module Configuration mounts to existing pallet flow rails and can be retrofitted to fit any existing pallet racking.

-

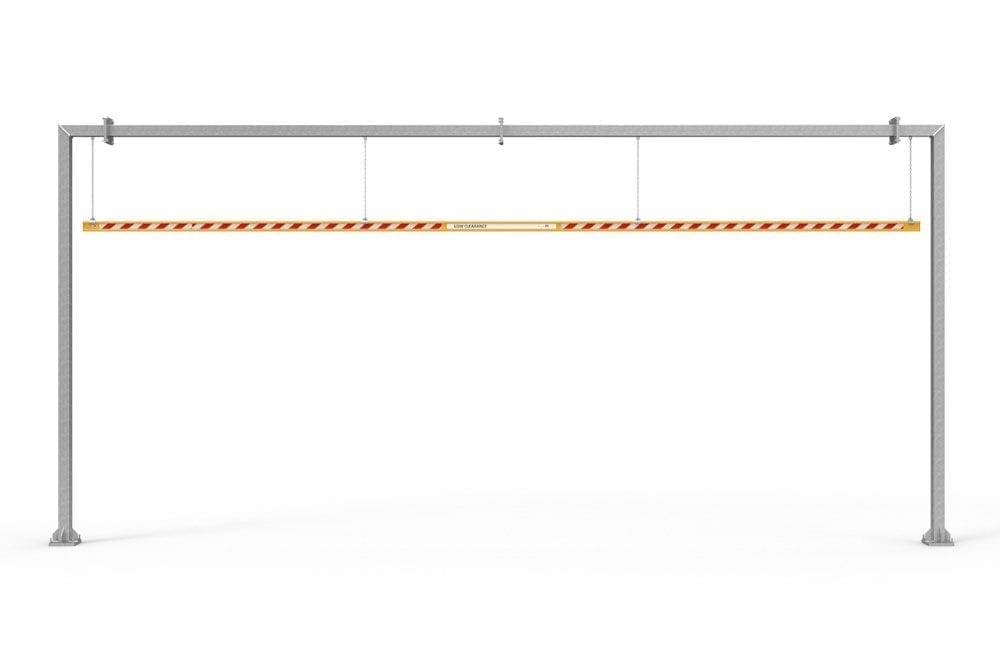

Height Bars

3rd March, 2017 | by excitemediaEliminate damage to vehicles and property caused by oversize vehicles entering areas of restricted height by installing suspended Height Bars. The Height Bars are available in three standard lengths: 2, 3 or 6 metres and come with suspension chain and hanger assemblies.

Powder coated safety yellow with reflected diagonal stripes, they carry the text “LOW CLEARANCE” with the specified height in black letters on a white background. (Please specify)

Use height bars at locations where vehicles first enter an undercover area or encounter an overhead obstruction, where the clearance in either case is;

(i) 3 metres or less if only cars or light vans are likely to use the facility or

(ii) 4.6 metres or less in all other areas. -

Hand Trucks Aluminium

26th September, 2023 | by Matthew BrittainOur Aluminium Hand Trucks are ergonomically designed and help reduce the physical effort required to lift, carry or transport heavy loads. Available in a range of designs, each Hand Truck is equipped with unique safety features that make them easy to operate. They are robust and sturdy with aluminium construction. This design allows them to handle a variety of materials and navigate various workplace terrains.

One of the most notable advantages of an aluminium hand truck is its weight, which is much less than that of a steel hand truck. Because of its lightweight design, this has the potential to significantly increase production and efficiency. This also guarantees that they are a cost-effective option. Aluminium Trolleys tend to lower the number of workplace accidents by inflicting significantly less harm to employees than steel hand trucks.

-

How to Choose The Best Storage Equipment

3rd October, 2022 | by support.gocreativeFinding the right storage equipment for your particular worksite isn’t always as simple as you might think. At Materials Handling, we provide numerous solutions for material storage, so it can be overwhelming to determine which is right for you.

That’s why we’re here to help you choose the best storage equipment.

How to choose the best storage equipment

\

What is storage equipment?

Storage equipment can include cabinets, lockers or any other storing solution that holds materials or items over a period of time. There can be many uses and applications of storage equipment and to one extent or another all industries and companies will require some level of storage solution to suit their needs.

The purpose of storage equipment

There can be many benefits to having a robust industrial storage solution. For starters, it ensures your products and items are protected, secure and safe. Additionally, it provides for better organisation and accessibility of tools and equipment which translates into increased efficiency and productivity. Last but not least, it ensures that your worksite, workshop or floor space is kept as clean and usable as possible.

What to consider when choosing storage equipment

When you’re looking for the right storage equipment to suit your needs, take the following factors into consideration.

1. Size and space

Where is the storage cabinet going? How much/many items are you planning on storing inside? What sort of shaped storage system do you need to fit into the desired area?

2. Safety and surveillance

Many storage cabinets come with locks and other safety features to ensure the items inside are secure. Think about what sort of products or materials you are storing and what level of security they require.

3. Accessibility and convenience

The level of accessibility and convenience of access will help narrow down the options to storage solutions that can either quickly open or provide for longer term storage with more safety features.

4. Work Environment

If the storage safe is likely to be exposed to the elements or other factors, you’ll want to prioritse heavy duty and durable storage solutions over less robust options.

5. Appearance

Of course, this factor is mostly subjective and up to your personal preferences. Nonetheless, choosing the right storage facility that suits the rest of your workspace will make for more aesthetic appeal in general.

Choosing proper storage equipment

Choosing proper storage equipment is vital to ensure your items are provided with the right level of safety and security from damage, theft or loss.

Every storage solution, whether it’s a cabinet or locker, offers different benefits and organisation arrangements. By spending the time and effort considering how you plan on using it and what you plan on storing inside it, you’ll find you and your entire team enjoying improved operational efficiency and productivity for a long time to come.

Not to mention the fact that raw or hazardous materials need to be stored in a regulation-compliant and heavy duty system. The last thing you want is damage or injury to property or workers.

Types of storage equipment

Flammable liquid safety cabinets

Some storage solutions are designed for particular uses, such as the flammable liquid safety cabinets. Manufactured in line with Australia regulations, they’re built for purpose and are perfect for housing flammable or otherwise dangerous goods. Special safety features are included as well such as vents with flash arresters or even self-closing doors on certain models.

Highly resistant cabinets

It’s not just flame and fire that you might be contending with. Even if the material being stored inside isn’t dangerous in and of itself, your cabinet or storage solution could be exposed to damage externally. Whether it’s fire, extreme temperatures, moisture (causing rust) or impacts from passing workers, machinery or vehicles, highly resistant cabinets will provide equal parts peace of mind as well as good protection.

Compartment cabinets

Keeping your equipment organised in storage is practical for many reasons. You’ll be able to fit more items into less space; you’ll be able to find and access more items quicker; and it will look professional and neat. Compartment cabinets are excellent storage equipment solutions for exactly that reason. Depending on the nature of the items you’re planning on storing, you can find and choose a style of compartments that works for you.

Adjustable and heavy duty

If you need to store big, heavy, bulky or oddly shaped items, an adjustable and heavy duty storage cabinet is the way to go. These types of cabinets and lockers often feature removable shelving or customisable designs so that it can work to meet your needs and not the other way round. Remember to check that the storage facility you’re considering has a load bearing capacity that suits your equipment.

Internal Safety Cabinets

Internal safety cabinets can be used for any number of items. Corrosive or otherwise harmful materials can be kept secure and out of the wrong hands, and personnel items can be stored out of sight and reach of would-be thieves or no-gooders.

Want the best storage equipment? You want Materials Handling!

For years Materials Handling has been assisting businesses in improving their productivity, efficiency and safety through our products and solutions. We don’t believe in a one-size-fits-all approach and love tailoring our materials handling solutions for our customers.

-

Dimensioning System iDimension LTL Pallet

23rd October, 2020 | by John BrittainThe iDimension LTL uses advanced sensing technology to determine the cubic dimensions of freight, ensuring that freight code compliance is recorded and declared. The iDimension LTL removes the potential for human error when taking measurements. iDimension LTL accurately captures freight dimensions in less than two seconds.

iDimension LTL Stop and Go Feature

Increases throughput of palletized dimensioning, the iDimension LTL Stop and Go feature provides an NTEP approved capability of measuring pallets without having to remove the forklift from the target zone for up to 1830 x 1830 x 2133mm {L x W x H} pallets and continue to achieve accuracy and less than 2 second dimension time.Refer to the PDF below for scales, options, accessories and parts.

-

Collision Alert Sensors Overhead Hazard

3rd March, 2017 | by excitemediaOverhead Hazard Sensors provide warnings to alert forklift truck drivers that an overhead obstacle is in their pathway. The units are activated when an operator moves a load or mast lifted at a dangerous elevated height that could potentially collide with a building asset. These Collision Awareness systems prevent damage to loads or buildings, accidents and personal injuries caused by such events.

Also known as ‘Fit’ Height Warning Sensors, our Overhead Hazard Sensors are ideal for a range of applications. They’re perfect for alerting individuals regarding sprinkler heads above racks, overhead heaters, overhead lights, ceiling fans, rack tunnels, overhead storage, air handlers and interior doorways. The sensors make workplace operations more safe and efficient.

-

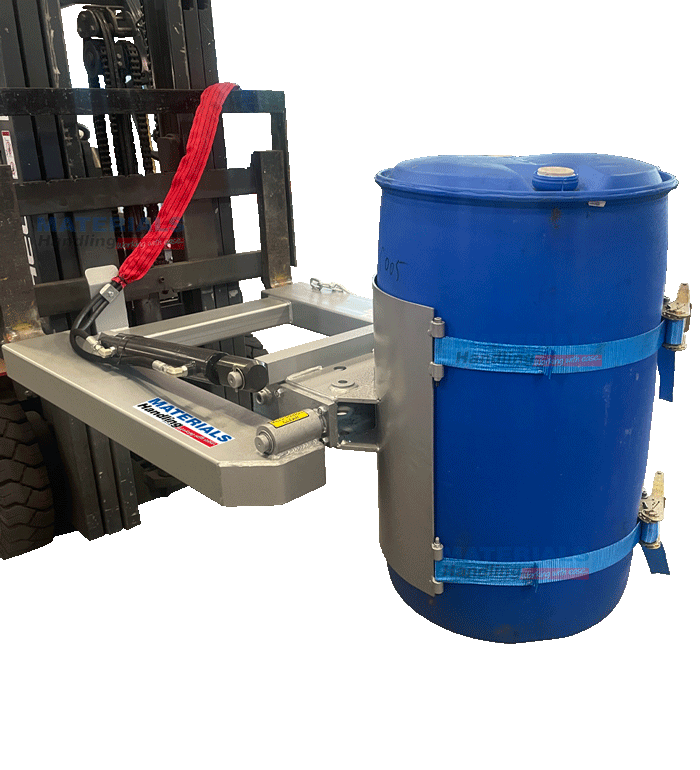

Drum Lifter Rotator Forklift Mounted Hydraulic

3rd March, 2017 | by excitemediaThis Hydraulic Drum Rotator effortlessly lifts and rotates 205-litre drums. As a reliable drum handling solution, it easily facilitates reliable and safe emptying or disposal of contents. For use with an existing forklift, the forklift hydraulics aid the drum rotation and the action is controlled by the third function lever.

The device features a heavy-lift capacity and can handle drums weighing up to 1000 kg. The Chain Belly Strap and eccentric lock hold the drum firmly and securely into position. This ensures the drum is supported during movement. If handling plastic drums, this device can be supplied as a Plastic Barrel Option (Model -PBO).

The Hydraulic Drum Rotator is commonly used in food processing, recycling, waste management, mining and warehouse industries and makes for a great hydraulic attachment.

Showing results for driver rods less equal d1 routes rotates205