Ball Transfers – Pop Up Ergonomic

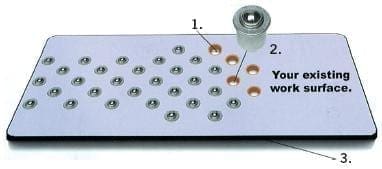

+ Add to Quote RequestPop-Up Ergonomic work surfaces to fit virtually any application or work bench. See the PDF below for further details on ball transfer strips, lift table surfaces, retrofit kits, ball and pad strips and many other ball insert surfaces. Ask our sales facilitators for a proposal today!

At the flick of a switch, the pop-up ball transfers raise above the surface to easily move items onto and off the work surface, while at same time allowing the item to be oriented/positioned.

Flip the switch again and the pop-up ball transfers retract so the item is solidly and firmly located on the work surface so the task required can be performed on the item without allowing it to move around.

Also view our Ball Transfers our Rotacaster Wheels as well as our Omni Wheels.

Additional Information

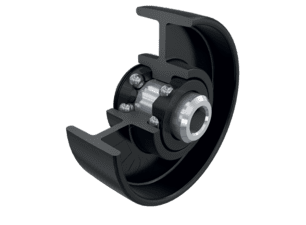

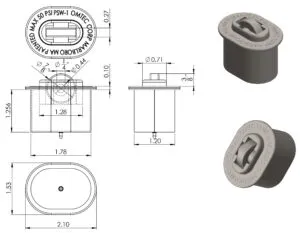

PBT Ball Transfer

Virtually any air control device may operate Pop Up Ball Transfers. Simple pneumatic foot and hand valves may be used in most applications.

Pop Up Ball Transfers (like virtually all pneumatically operated components) require Filtered, Regulated and Lubricated compressed air to operate. We can provide FRL kits, non-detent foot valve kits and detent toggle hand valve kits. Other controls are supplied on request. The regulator should be set at 50 PSI (3.447 bar). Pop Up Ball Transfers use very low air volume to operate. Each up-and-down cycle of one ball uses 0.0000108 cubic meters of air.

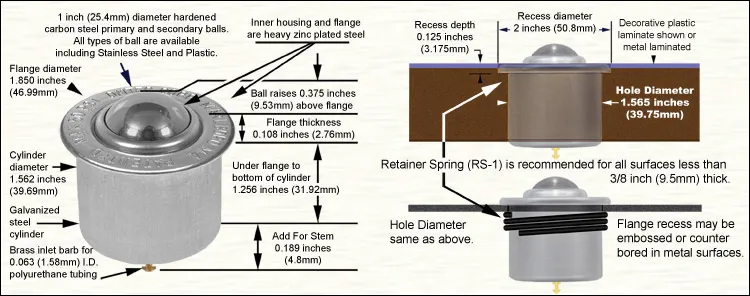

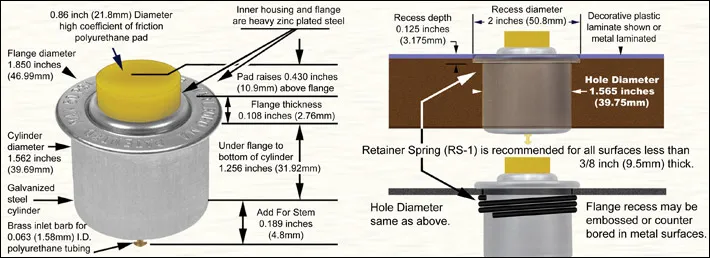

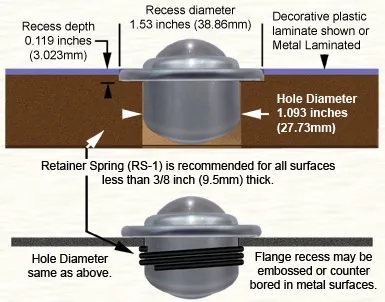

Carbide bits for boring and recessing holes in plastic and wood composite surfaces. We can supply carbide-tipped bits to easily bore holes for Pop-Up Ball Transfers. 1/2 inch (13mm) hand drill required. If recessed flanges are desired, we can supply carbide-tipped rabbeting bits. 1/4 inch (6.35mm) trim routers. Minimum metal surface thickness: Steel 2.34mm, Aluminum 3.18mm. Depending on individual applications, ribbed reinforcement of all surfaces is a consideration.

Ball Transfer Weight Capacity: 22.68 kg

Ball transfer weight capacity can be deceptive. Many factors override the actual rated capacity of a ball transfer. Experience indicates when all factors are considered, the most successful live load rates of ball transfers fall between 2.27 to 13.61 kg per ball transfer.

PBT ball transfers are designed to be used in combination with all of the other Ergonomic Transfers. They are ideal with: PPD Positioner Pads, FBT Ball Transfers, Insert Wheels, Insert Rollers and the ESD PUG Grounding Device.

PPD Positioner Pads

PPD Positioner Pad capacity: 20 lbs. (9.07 kg) each.

The following factors need to be considered…

- Weight (is it evenly distributed?)

- Foot Print (bottom size)

- Item bottom characteristics, hard, solid, flat and smooth?

- Are the pads likely to indent the bottom surface?

Designed to raise under an item firmly holding it in location, not as stops, using as conveyor, stops will destroy them.

PSW-1 Transfer

PSW-1 units are designed for the linear movement of your product. Using a wheel instead of a ball allows for a larger surface area when moving products. This comes in very helpful with pallets. Ball transfers and pallets do not transfer well due to the small contact area a ball has. With the PSW-1 OMTEC can now transfer your pallets much easier. Pop-up Skate Wheels allow for easy 90-degree transfers of products and inline workstations, and you can even create your own 90 or 180-degree turn within a work cell.

Skate Wheel Transfer Weight Capacity: 22.68 kg

PSW-1 transfer weight capacity is deceptive! Many factors override the actual rated capacity of a ball transfer. Experience indicates when all factors are considered, the most successful live load rates of ball transfers fall between 2.27 to 13.61 kg per ball transfer.

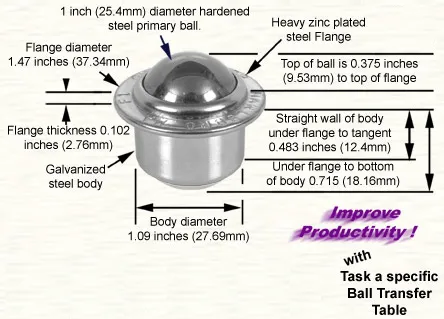

F1 Fixed Ball Transfers Flange Mount

Ball Transfer Table is available in any size or shape. The fixed ball transfer is ideal for easy minimal effort moving and orientating of an item on a workbench. Ideal for retrofitting your existing industrial workbench, the Fixed Ball Transfer is available with a type of ball, including Steel, Stainless Steel and Plastic. F1 Ball Transfers are available as individual hardware items or kits for your application. They are also available as complete ball transfer tables of any size, shape or ball transfer pattern.

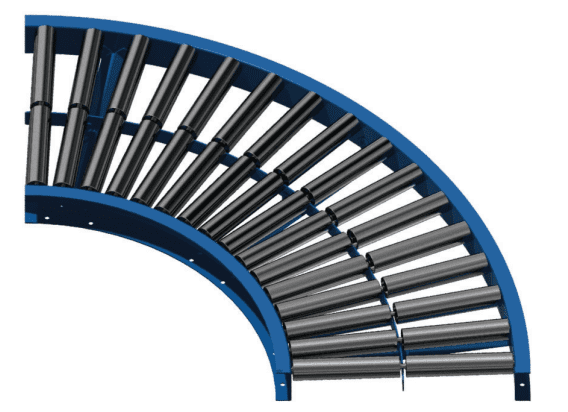

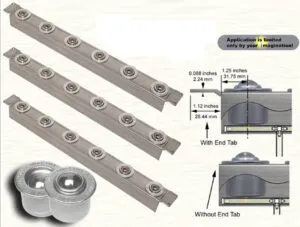

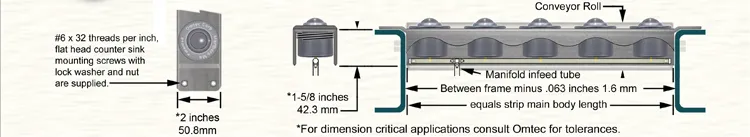

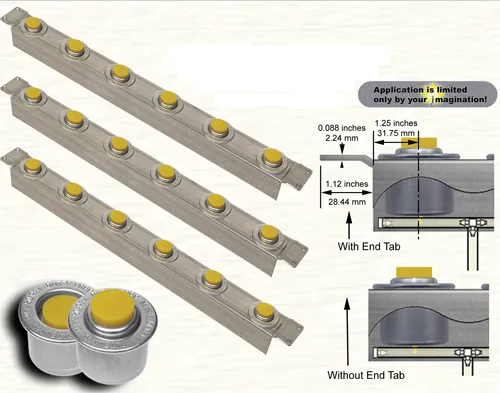

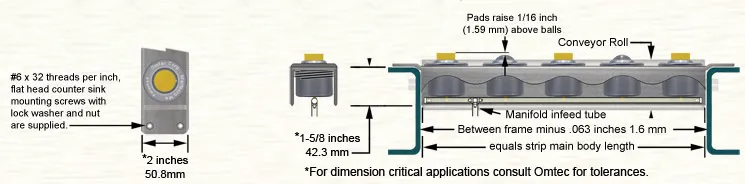

PBTTM Pop Up Ball Transfer Strips

Pop Up Ball Transfer Strips are ideal for roller conveyor transfers and repositioning stations. PBT Ball Transfer Strips are available with end tabs for mounting in conveyor lines or without end tabs for your application.

At the flip of a switch PBT Ball Transfer Units raise above the conveyor rollers to move items off the conveyor line with minimal effort.

Flip the switch again PBT Ball Transfers retract below the conveyor rollers allowing items to move on the rollers unaffected by the ball transfer strips.

Standard solution is to place the first and last pop up ball transfer 31.75mm C/L from each end of the main body (between frame dimensions). The other pop ups are evenly spaced.

PBT Pop Up Ball Transfer Strips may be any length. The number of Pop Up pneumatic Ball Transfers on a strip may vary and be located on any desired centre line. The minimum centre line is 50.8mm.

PBT Ball transfers are pneumatic (air-operated).

The air supply line is a single 0.180 I.D. X 0.265 O.D. polyurethane tube under the strip between the first and last ball. The standard supply tube is 203mm long between the first and second ball but can be any length or location on the strip.

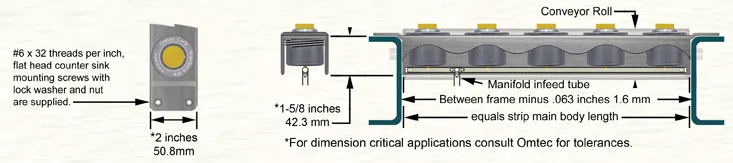

PPD Positioner Pad Strips

PPD Positioner Pad Strips are ideal for roller conveyor assembly workstations!

Standard solution is to place the first and last PPD Positioner Pads 31.71mm C/L from each end of the main body (between frame dimensions). The other PPD Positioner Pads are evenly spaced.

PPD Positioner Pad Strips may be any length. The number of PPD Positioner Pads on a strip may be varied and located on any centre lines desired. The minimum centre line is 50.8mm.

PPD Positioner Pads are pneumatic (air-operated).

The air supply line is a single 0.180 I.D. X 0.265 O.D. polyurethane tube under the strip between the first and last ball. The standard supply tube is 203mm long between the first and second ball but can be any length or location on the strip.

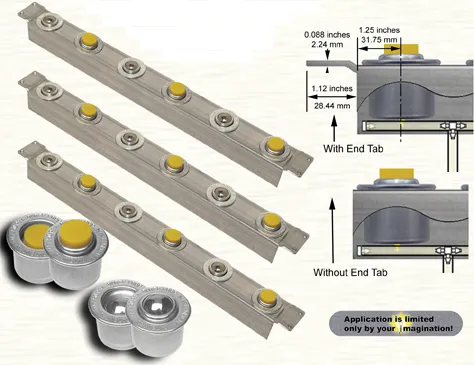

PBT Ball Transfer & PPD Positioner Pad Strips

Pop Up Ball Transfer Strips are ideal for roller conveyor transfers and repositioning stations. PBT Ball Transfer Strips are available with end tabs for mounting in conveyor lines or without end tabs for your application.

At the flip of a switch PBT Ball Transfer Units raise above the conveyor rollers to move items off the conveyor line with minimal effort.

Flip another switchPPD Postioner Pads raise the item above the PBT Ball Transfers to locate the item in a firm stable position allowing a task to be performed.

Retract the PBT Ball Transfers and PPD Positioner Pads to allow items to continue down the conveyor line unaffected by the Strips.

Standard solution is to place the first and last PBT Ball Transfer and PPD Positioner Pads 31.75mm C/L from each end of the main body (between frame dimensions). The other PBT Ball Transfers and PPD Positioner Pads are evenly spaced.

PBT Ball Transfer and PPD Positioner Pad Strips may be any length. The number of Pop Up pneumatic Ball Transfers on a strip may vary and be located on any desired centre line. The minimum centre line is 50.8mm.

PBT Ball transfers and PPD Positioner Pads are pneumatic (air-operated).

The air supply line is a single 0.180 I.D. X 0.265 O.D. polyurethane tube under the strip between the first and last ball. The standard supply tube is 203mm long between the first and second ball but can be any length or location on the strip.

Click the PDF button to learn more.