Gantry Cranes – Workstation

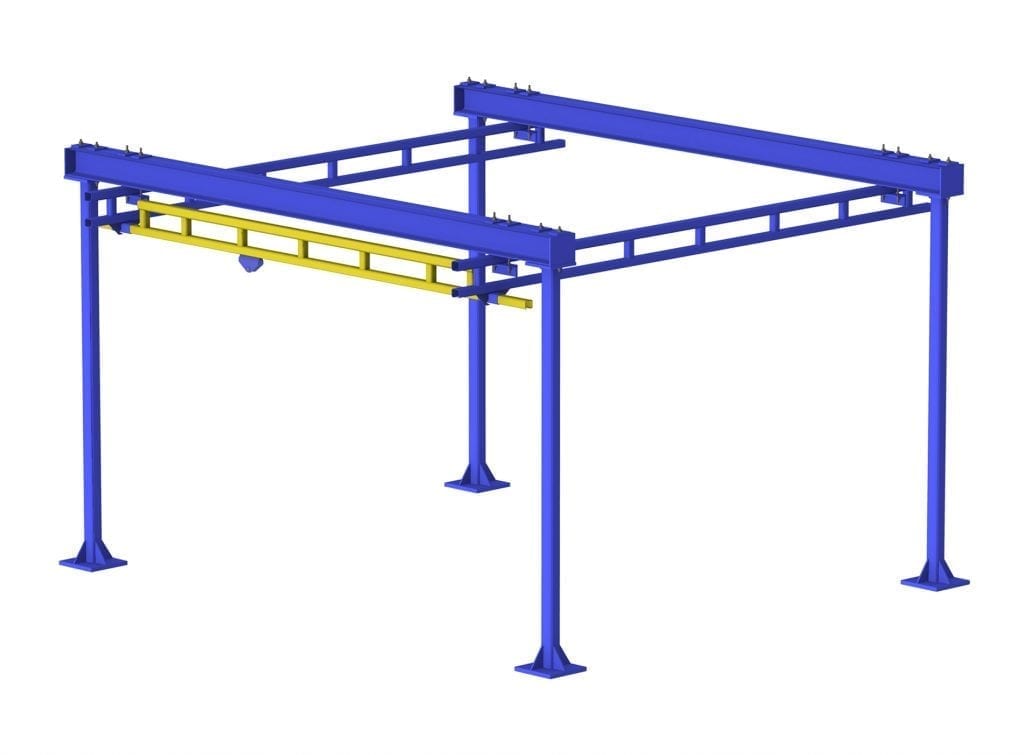

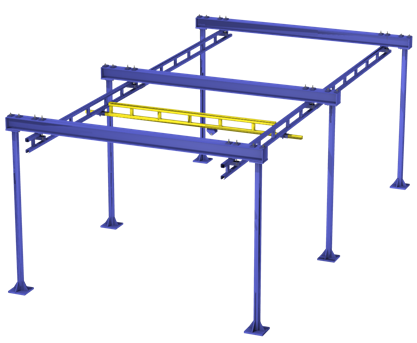

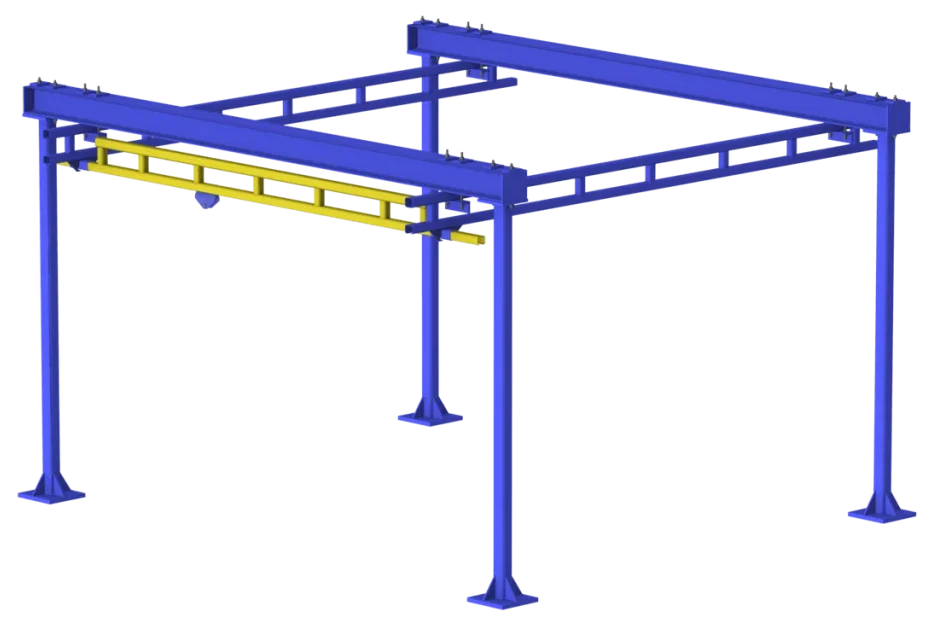

+ Add to Quote RequestOur Gorbel Workstation Gantry Cranes (sometimes called Bridge Cranes) provide the ideal solution for an ergonomically effective, flexible and efficient handling assistant! Lifting and shifting from above is often the easiest way to solve manual handling problems. Available as a ceiling-mounted, free-standing or monorail solution, they are solid and easy to operate.

The steel-enclosed track is a lightweight crane profile that assists in increasing productivity and getting the job done. They can span up to 10 metres and have various profiles and configurations capable of handling loads up to 2000 kg.

Additional Information

Gorbel Bridge Cranes are configured to suit your lifting requirements

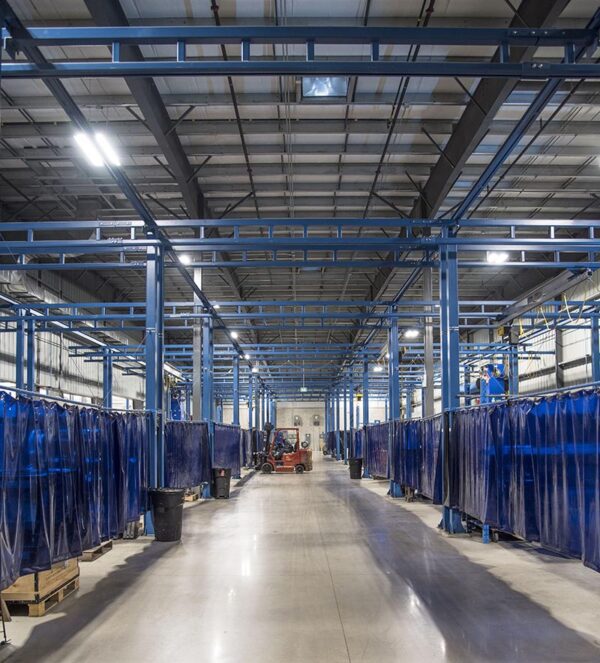

Gorbel Workstation Gantry Cranes are a proven way to improve productivity and quality in your working environment. They are constructed from robust steel enclosed track profile that is strong and lightweight. Installation is uncomplicated and they can be flexibly relocated for future use.

What Type of Crane Is Most Appropriate?

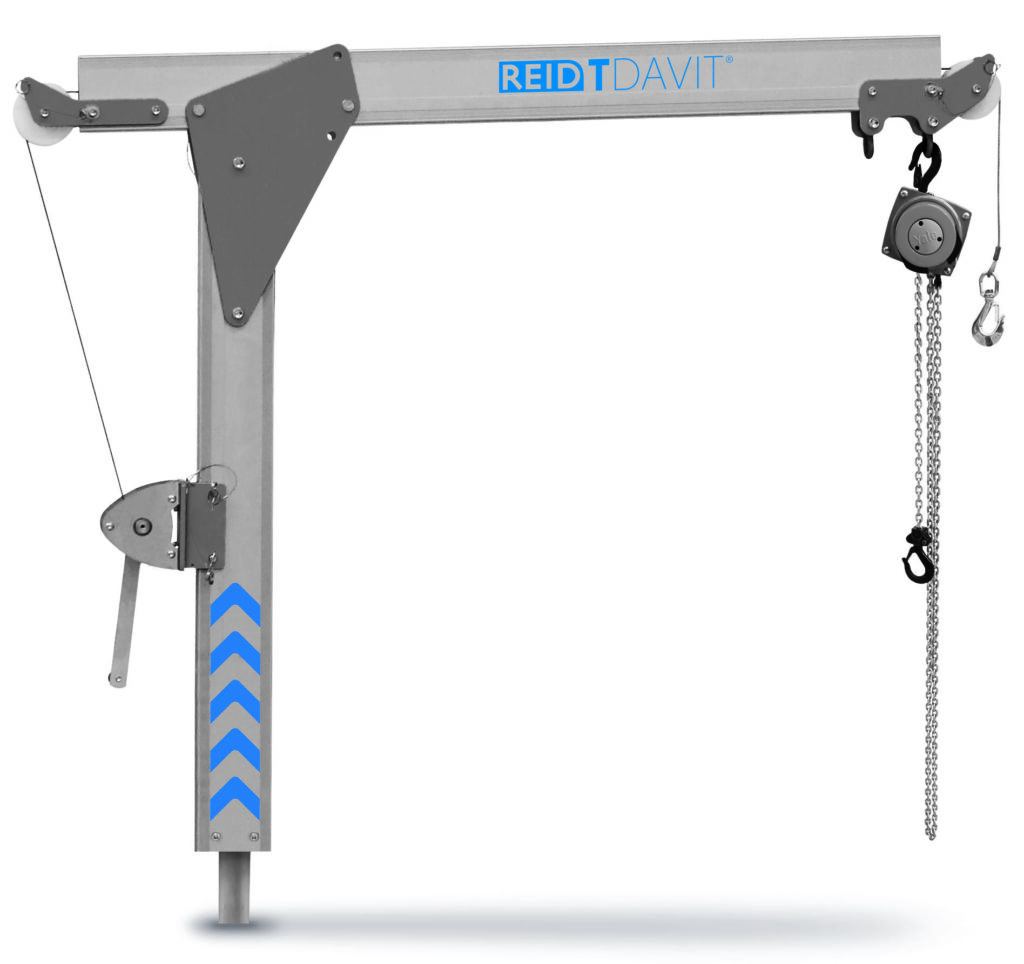

- Bridge cranes cover rectangular areas, while jib cranes cover circular areas.

- Bridge cranes can be floor mounted or hung from the ceiling. Jib cranes can be wall or pillar-mounted and may require a special foundation.

- An enclosed track work station bridge crane provides consistent ease of operation over the full range of movement.

- Jib cranes move more easily at the very end of the boom and are more difficult to move as the load approaches the pivot point.

Should the crane be manual or motorized?

Ease of movement and low weight are key features of enclosed track workstation crane systems. Manual workstation cranes can do the job faster than motorised cranes. If the operator cannot control the load throughout the operation (for instance, over a pit, or other inaccessible area), then the crane should be motorised.

What type of suspension: free standing or ceiling mounted?

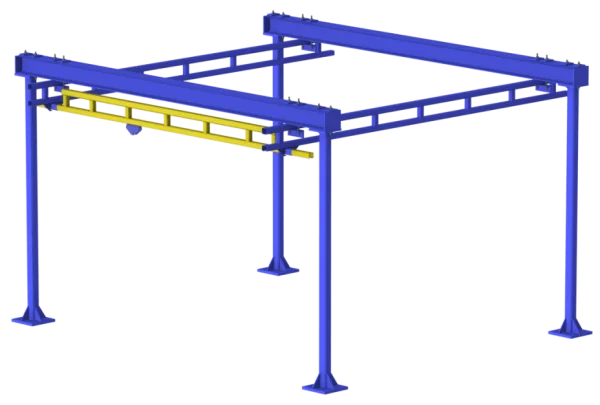

- Free-standing (floor mounted) systems do not put stress on the overhead structure of the building. Installation is usually more simple and these cranes are also easier to relocate in the future.

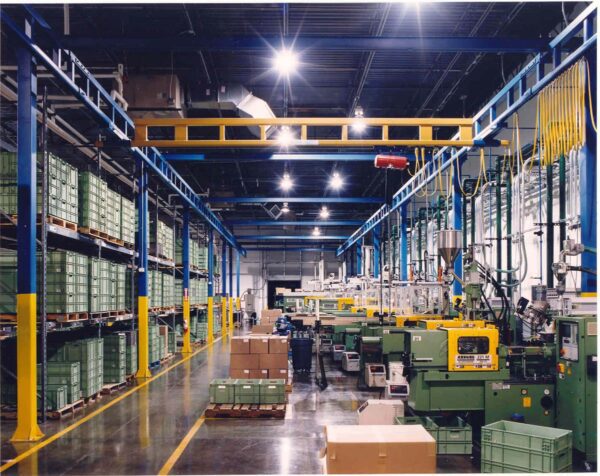

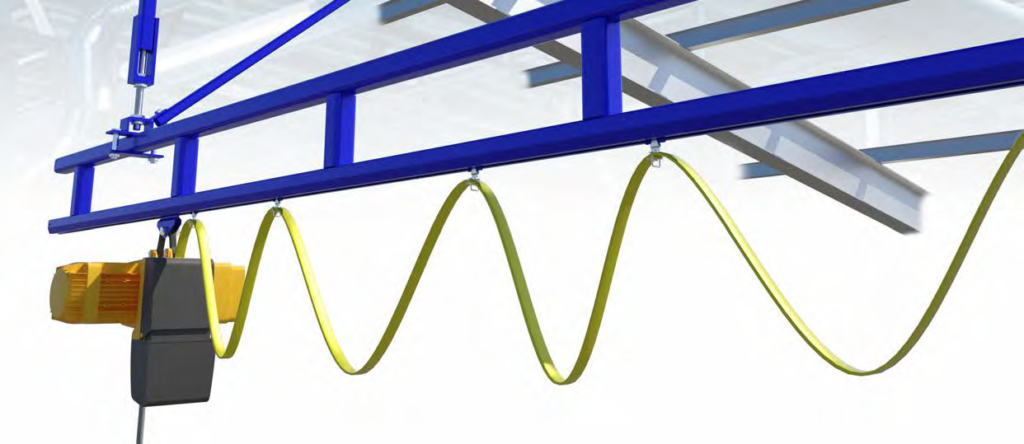

- With ceiling-mounted systems, supporting steel does not interfere with traffic flow around the workspace. Ceiling-mounted systems require a building with an adequate overhead structure to suspend the crane.

What capacity, bridge length, and height?

The general rule is “less is more”

- Keep capacities to a minimum. Gorbel Bridge Cranes are designed with an adequate safety factor. If you “over-buy” capacity, the operator will need to move extra bridge dead weight, which would not be a good ergonomic solution. Buying a 2 tonne crane to handle 500kg loads is not a clever move.

- Keep bridge lengths to a minimum. The less dead weight an operator has to move, the better. Short bridge lengths are better for higher-cycle production areas. Longer bridges are acceptable for lower-production cycle or maintenance areas.

- Keep bridge heights (trolley saddle) to a minimum. Keeping the trolley saddle (TS) height less than 4 metres is desirable because it makes it easier to control and position the load.

Can the operator safely move the load?

- A work cell should be designed so a task can be performed by 90% of the workers.

- A worker should not exceed 33% of his or her capacity; otherwise, the risk of chronic fatigue increases.

Bridge cranes offer several benefits:

- Enclosed tracks – long-lasting and easy movement.

- Rigid runways – no “crab-walking” of the bridge or additional movement ensures superior load positioning.

- Easy installation – simple to install.

- Smooth-rolling surface – easy movement of bridge and load trolleys.

- Multiple track profiles and spanning capabilities – these units are adaptable and cost-competitive.

What are your requirements?

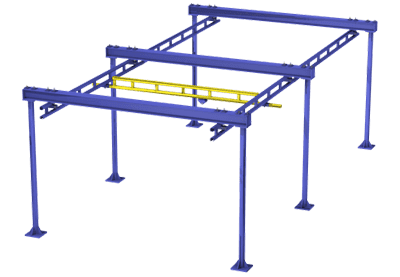

Bridge Cranes come in the following typical arrangements:

- Ceiling Mounted – Incorporates two parallel runways (tracks) and a bridge rail (crane rail) spanning between the two. Provides full lifting coverage over a rectangular work area.

- Freestanding – Same as above however the runways are supported from a freestanding structure.

- Monorail – A single crane rail supported from the ceiling or a freestanding structure.

Want to learn more?

Let us help you custom order your own Gorbel Crane System, contact one of our sales representatives to help you identify the right requirements!

Click the PDF button to learn more.