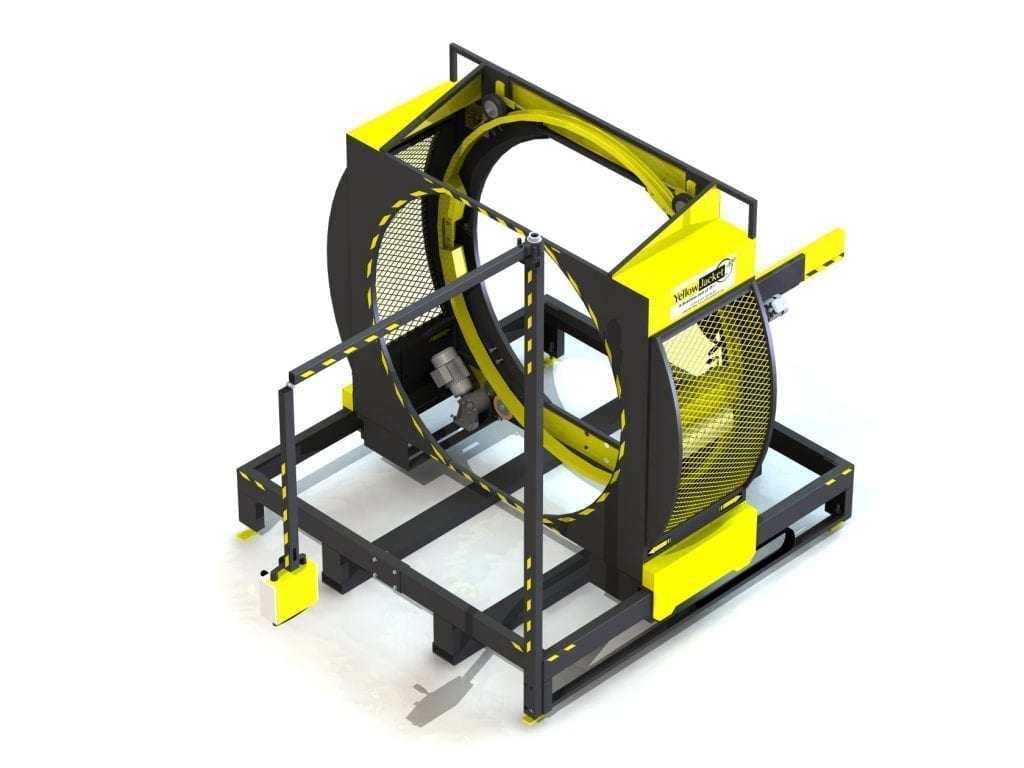

Orbital Stretch Wrappers

+ Add to Quote RequestOrbital Stretch Wrappers offer unique, fast and secure wrapping of long products. Whatever the shape of the item, our wrappers will seal with ease ensuring products are protected and ready for shipment. Orbital Wrappers provide a great return on investment, thanks to their low energy consumption and automated process, which improve productivity and user ability.

Orbital Stretch Wrappers wrap and protect products, keeping them free from contamination and collateral damage. The finished goods are always well-presented and free from dirt, dust and humidity, which often impacts products during transportation and storage. All our stretch wrappers are equipped with PLC electronic controls and inverters to regulate wrapping speed and the speed of powered conveyors.

These two models are available to suit varying organisational requirements and include the Semi-Automatic (NELEO) and Automatic (ATIS) units.

Additional Information

Orbital Stretch Wrappers offer product protection to its final destination.

Our wrappers are technologically advanced and very safe. They are completely versatile, as products of differing lengths, diameters and shapes can be wrapped without adjustment. They improve working speed while saving on manual labour. Various models are available including the Semi-Automatic ‘Neleo’ range and the Automatic ‘Atis’ range.

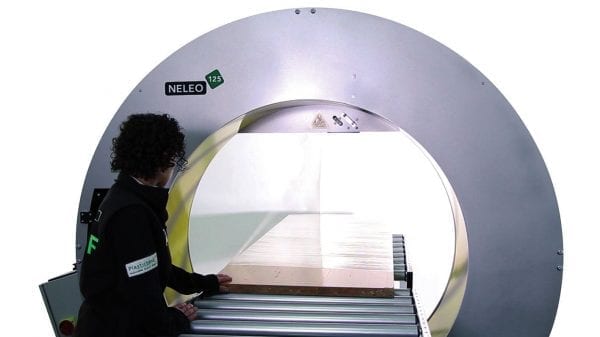

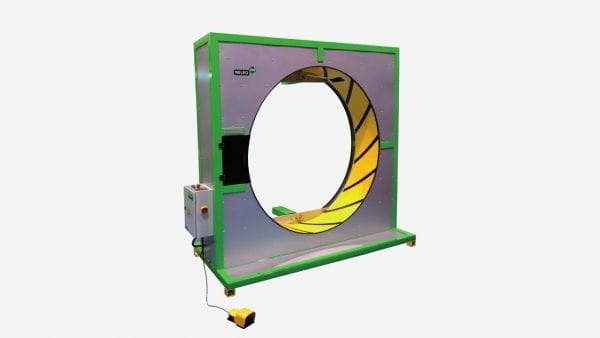

Semi-Automatic Orbital Stretch Wrappers:

Also known as the ‘Neleo’ range, these machines are equipped with a safety foot pedal switch, speed adjustment, ring protection, adjustable stretch-film tension, control panel, double film reel dispenser head and electrical cabinet.

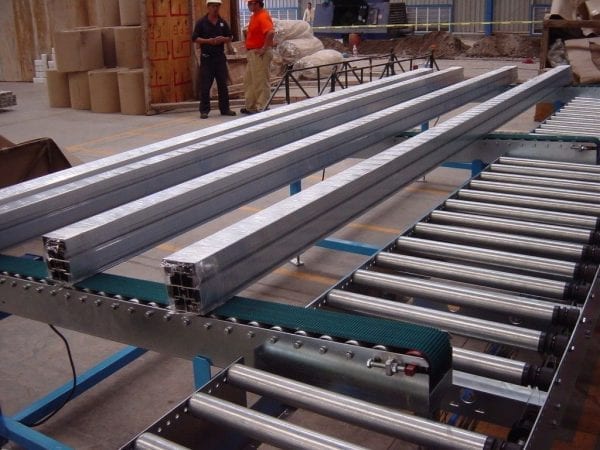

A great option for any kind of product – from small profiles to furniture. It is designed with two film reels. The wrap of the film around the product is via a speed control inverter with a foot pedal for the operator. At the end of the cycle, the film is automatically cut (includes 3 programmes) and sealed with the package perfectly wrapped. The P50, 90, 125, 160, 200 and 250 models with ‘S’ suffix are manually operated and can be optionally supplied with gravity infeed & outfeed conveyor in 230, 1000, 2000 & 3000mm lengths for the P50S and P90S. Gravity conveyors 1000mm long are available for the P125S, 160S, 200S and 250S models. Order these conveyors separately.

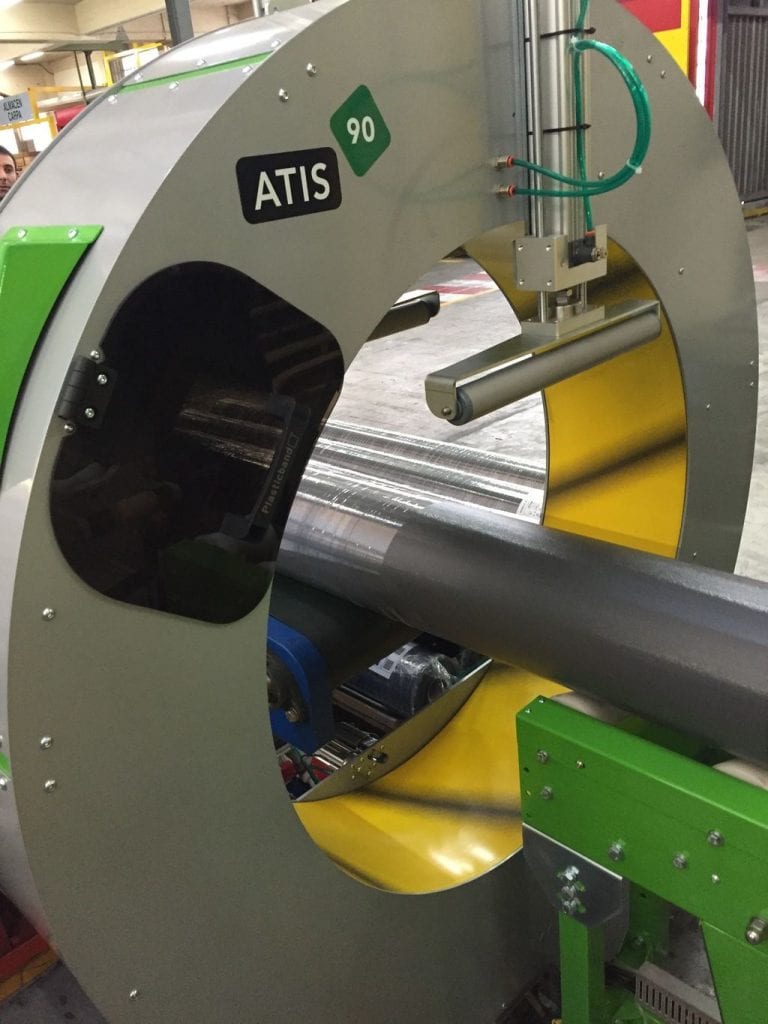

Automatic Orbital Stretch Wrappers:

Also known as the ‘Atis’ range, the basic machines are supplied with ring protection, adjustable stretch-film tension, photocells, control panel, double film reel dispenser head, touch screen to manage settings and electrical cabinet.

This model is a packaging solution that can handle any kind of product. It is adapted for automatic lines or high-performance solutions. The P50, 90, 125, 160, 200 and 250 models with ‘A’ suffix are similar to the semi-automatic machines but are used for faster production. The conveyor rollers are substituted for powered rollers with an in/outfeed. The conveyors and the rotating ring speed are controlled by an inverter. The start and finish cycles are controlled by photocell sensors. They have automatic film cutting and sealing together with self-adjusting top pressure rollers that assist when wrapping lightweight items.

When requesting a quote for our ATIS systems we ask for the questionnaire to be completed as we want to offer the best unit for you as there are many options & extras.

Also, ask our sales facilitators about our Orbital Wrapper with Bubble Wrap Automatic wrapping for horizontal wrapping with stretch film and final bubble wrap protection.

Continue browsing more of our Stretch Wrapping range!

Click here to view our ‘Artemis’ range of Orbital Wrappers, which have been designed specifically for rolls (available in an automatic and semi-automatic model).

Click the PDF button to learn more.