Loading dock safety

Safety is always of paramount importance in a work space. When it comes to a loading dock, safety is all the more necessary.

Safety is always of paramount importance in a work space. When it comes to a loading dock, safety is all the more necessary.

There is always a lot of activity on a loading dock. With arrivals coming in and shipments going out, even the most well-managed and organised workplace needs to keep a firm eye on safety at all times to ensure risks are minimised and mitigated.

Want to find out more about our dock eye safety lights?

Check out our dock guard safety gate manual.

Loading Dock Factors

Due to the fact there are often so many moving parts to a successfully working loading dock, there are also an equal amount of factors that need to be accounted for and controlled to ensure safety.

Due to the fact there are often so many moving parts to a successfully working loading dock, there are also an equal amount of factors that need to be accounted for and controlled to ensure safety.

-

-

-

-

-

-

- Employee training

- Competent engineering controls

- Efficient logistics

- Operating and safety procedure

- Variable control

-

-

-

-

-

Being able to stay on top of these different factors will enable you to minimise the likelihood of an accident and thus injury and/or asset damage.

Standard operating procedure

The standard operating procedure refers to the laid out policies and protocols to ensure work is done in a safe and responsible manner. This can include inspecting incoming and outgoing loads, proper disposal of material and correct use of locking devices. Every procedure will be unique to the workspace in question and should be constantly reviewed and updated.

Cleaning and other housekeeping

Keeping your loading dock clean and kept is an unsung hero of safe operation. There’s often a lot of traffic and movement on a loading dock so the area should be kept free of debris, hygienic and clean. If you deal with hazardous or other potentially risky material, it’s even more important you have a good cleaning and maintenance structure in place.

Training

Employee training is absolutely vital for ensuring everyone knows how to safely operate the various equipment on a loading dock and conduct themselves in a safe manner. From operating machinery to understanding vehicle capabilities, and from ergonomic lifting and carrying to wearing personal protective equipment (PPE) when necessary, and even knowing the risk management and incident protocols and procedures, training isn’t a one-and-done thing. It’s an ongoing commitment to ensure your loading dock remains safe.

Engineering controls

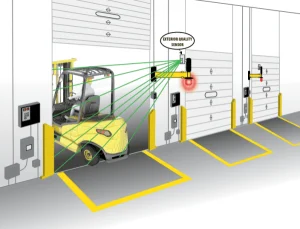

Engineering controls are there to reduce risks and hazards. They can include something as simple as highly visible paint on areas that can prove hazardous, to elaborate electronic systems, automated machinery and the like.

Logistics

The more efficient your logistical plans the better your loading dock will operate. Of course, even the smoothest of facilities will find storage spaces full at some point and your loading dock will need to step up. However, having a robust logistical plan and operating procedure will not only ensure that your safety policies are adhered to but will also safeguard your assets from damage or loss. A strong loading dock safety plan and logistics plan go hand in hand.

Managing loading dock safety

Workplace health and safety is an ongoing work in progress and often managing it successfully requires double checking and ongoing development of your controls and procedures. The important thing to remember is that no matter how much time and energy you invest into the safety of your workers and worksite, it’s always worth it.

To help you in your journey, the team at Materials Handling is always on hand to give you help finding the right equipment, accessories and loading dock safety tools.