Vacuum Lifting Airport Baggage Handling Solutions

+ Add to Quote RequestVacuum tube lifters are an ideal solution for baggage handling in airports and cargo terminals.

It is a known fact that a huge number of items are handled at airports every day and these tasks are completed manually. Injuries can result from repetitive stress, manual handling and incorrectly moving heavy objects. Vacuum Tube Lifters are a proven solution, specifically designed for airports and baggage handling. They help eliminate manual handling injuries from any workplace.

Ergonomic Vacuum Lifting increases productivity, efficiency and minimises strains/injuries. Our airport baggage handling solutions can be installed and used virtually anywhere. Where there is a need for an intelligent lifting device – Materials Handling Pty Ltd has the solution for you.

Additional Information

It’s an arduous and potentially unsafe task when moving thousands of pieces of luggage and baggage worldwide. Unloading and loading bags for hours can cause fatigue and employee health risks (like bad posture or musculoskeletal disorders).

Vacuum lifting has simplified this process and reduced the effort required with manual handling. Baggage becomes almost weightless, as it can be moved into position with a single hand that engages the vacuum lifting device. Independent ergonomics analysis shows that the risk of personal injury can be decreased by up to 80% by using vacuum tube lifters for Airport Baggage Handling solutions. When it comes to Airports we have a number of solutions available.

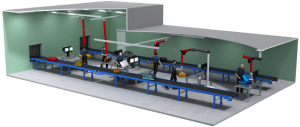

We have options to assist in operations at airports and relative industries. With a variety of methods to assist in the handling of heavy objects, you can guarantee the vacuum handling solution will save you time and energy. Transform your processes into a seamless ergonomic vacuum lifting solution and reap the benefits. Some examples of these systems in action are below.

Loading Baggage from Chute to Open Cart

At many airports, checked baggage is dropped via an automatic conveyor chute for sorting. The luggage is then moved from this chute into carts or barrows, which are transported to an aircraft. These ergonomic lifting systems easily handle heavy bags. Even the most inconvenient and limited working spaces can benefit from these devices.

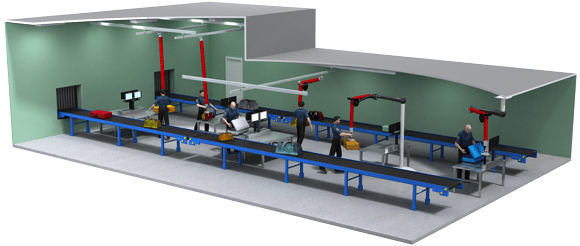

A diagram of operators moving baggage between chutes and open carts.

No bending required as vacuum lifting does the work for you.

Lifting devices can be operated by any person.

The suction grips onto all types of material.

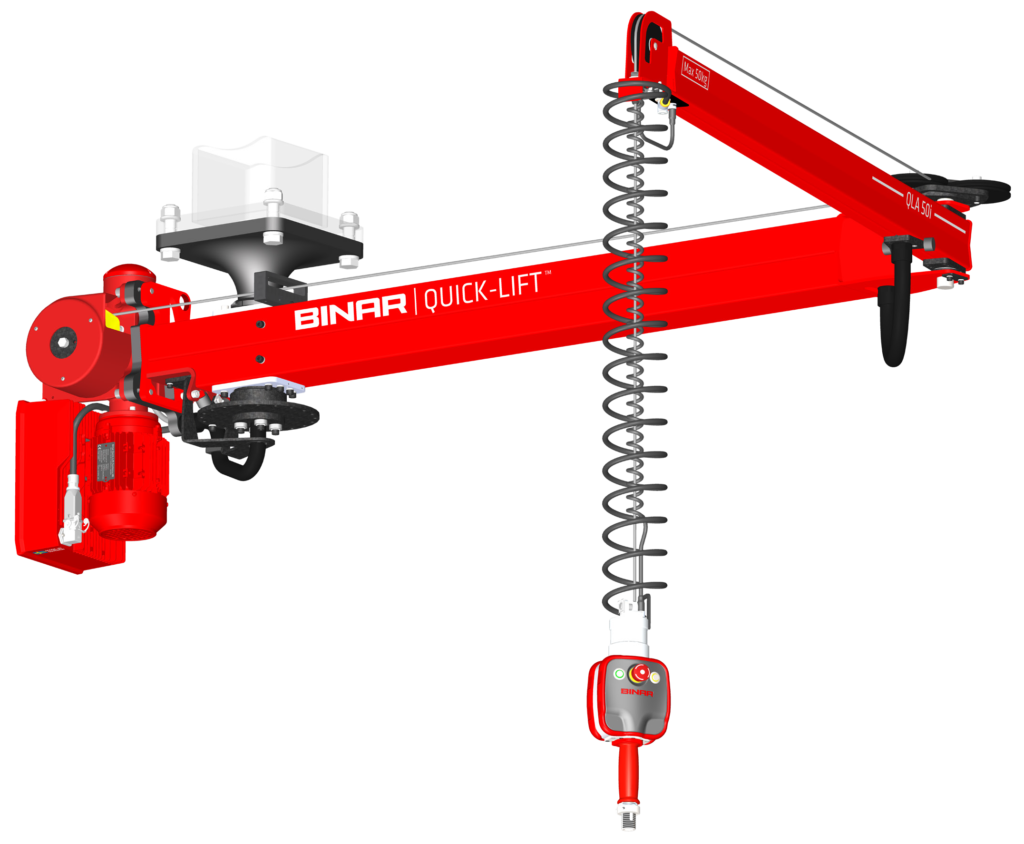

When it’s time to unload baggage from an aircraft, items are loaded onto carts that are transported to terminals for passenger collection. In a terminal luggage will be loaded between carts and conveyor systems. Our specially developed lifting systems are ideal for high workloads and bags up to 50 kg. View operators using vacuum lifters partnered with our smart lightweight crane.

Operator requires minimal effort when utilising Vacuum Lifting to move luggage from conveyor to cart.

Easily attaches to baggage with unique suction power.

Operator safely sets luggage to destination. It’s simple to lift heavy baggage and handle with ease.

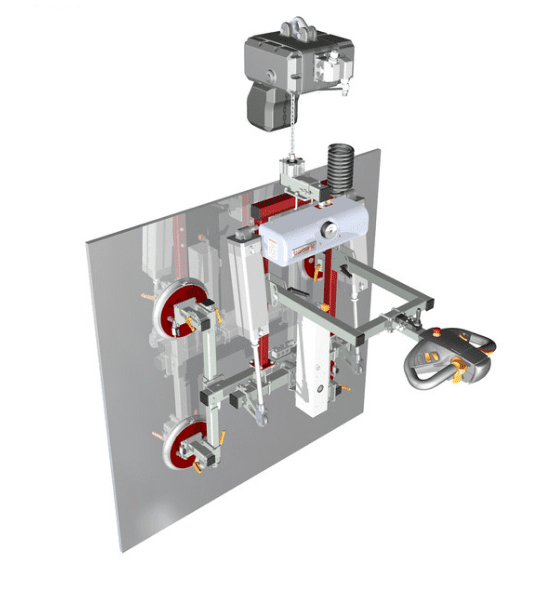

Baggage that is suspicious is diverted to a Checked Baggage Reconciliation Area (CBRA) and must be lifted/moved for screening (prior to luggage being transferred to outgoing conveyor). A specially designed vacuum lifting solution for this area enables transferring and lifting of bags without injury. With consideration to confined spaces, tight working heights and building columns (requiring flexibility), vacuum lifting improves productivity within airport processes.

The most common solution is ideal for areas with a normal ceiling height. The vacuum lifter and Bridge Crane are used in this image.

A unique solution perfect for CBRA rooms with low headroom.

Maximum flexibility is provided with minimal deployment costs in this unique solution.

We provide solutions for building and breaking down air cans and loading and unloading containers. We have developed lifting systems to specially move air cargo parcels between ULDs (Unit Load Devices). Moving cargo between pallet type of ULDs (PAG, PYB etc) or open type container ULDs (AKH, AAX) and loading or Unloading Large Container type of ULDs (AMJ, AAX, AAC, AMX, AML, AMJ, AAA, AMD).

It is a serious and heavy burden loading and unloading ULDs manually. Such activities cause a lot of stress on the body and can lead to serious injuries. We have developed a number of solutions to facilitate this problem and ease the handling of goods between ULDs. With a focus on the two major types of ULDS – Pallet and Container – vacuum lifting was able to move goods between devices and reduce manual labour.

Sorting goods between pallets and containers can be performed efficiently and effectively with minimum stress on the body.

It’s easy to unload a container, as vacuum lifting devices move heavy loads with minimal effort required. This lowers injury and bad postures considerably.

The lifting device is extremely versatile and handles a huge variety of goods with ease. It’s the best solution when it comes to minimising manual handling risks.

Want to know more?

Vacuum tube lifters have been implemented in airports across the globe. One of the case studies is with Air Canada. The company wanted to improve their baggage handling processes and reduce injuries in the workplace. Download the Airport Technology Special Report, “Next Generation Lifting Solutions for Future Airport Baggage Handling Operations”.

You may also like…

-

Gantry Cranes Mobile Aluminium Porta-Gantry Rapide

Gantry Cranes Mobile Aluminium Porta-Gantry Rapide -

Jib Cranes – Portable MobiCrane

Jib Cranes – Portable MobiCrane -

Lifting Trolleys – Multilift

Lifting Trolleys – Multilift -

Chain Hoists – Manual CX Series

Chain Hoists – Manual CX Series -

Vacuum Tube Lifter Easyhand Pro

Vacuum Tube Lifter Easyhand Pro