Manual Handling of BOC Gas Bottles

BOC approached Materials Handling Pty Ltd for assistance with a handling issue inside their refrigerant refill area. The aim was to reduce the manual handling of empty and full refrigerant bottles.

BOC approached Materials Handling Pty Ltd for assistance with a handling issue inside their refrigerant refill area. The aim was to reduce the manual handling of empty and full refrigerant bottles.

Removing empty or partially empty refrigerant bottles from stillage’s posed an Occupational Health and Safety issue. Continuous movement to a scale for recovery and constant refilling and reloading into stillage’s put considerable pressure on employees. Weights of refrigerant bottles ranged from 7-100 kilograms. The high repetition and volume of product put operators at risk of back and should injuries.

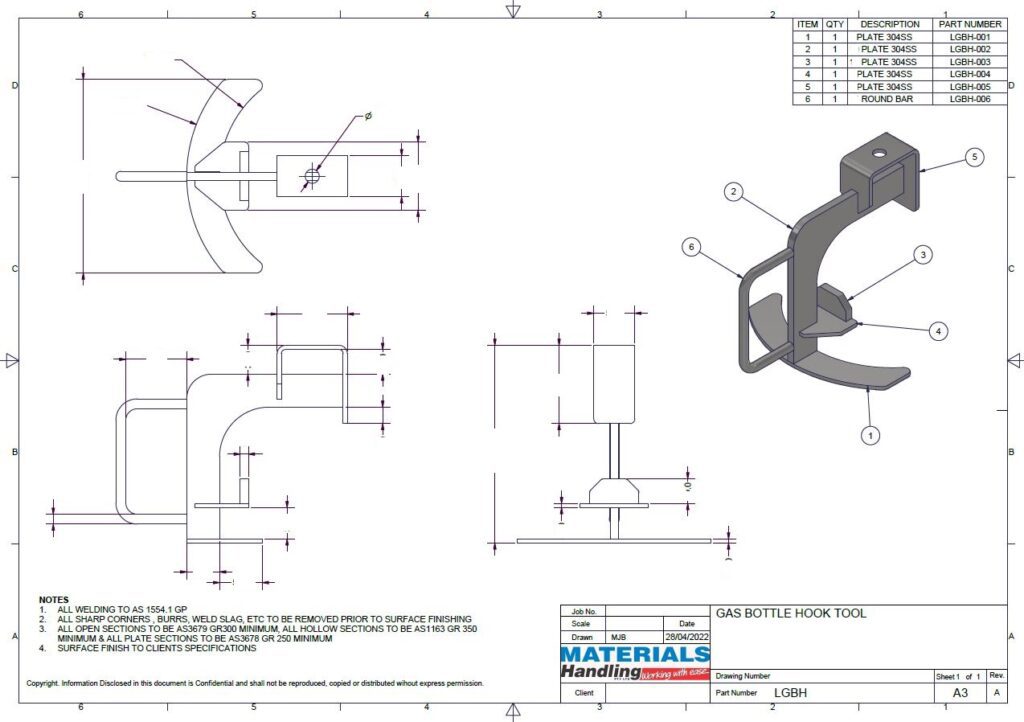

Materials Handling Pty Ltd had to design an end tool that would cover all styles of bottles, whilst keeping the vertically positioned. The tool was created to replicate lifting a bottle by hand, keeping it vertical. This was then complimented with a lightweight workstation Bridge Crane and an Intelligent Assist Device (IAD). The crane provided a 36-square-metre work area. Its low mass also reduced the effort required for an operator to move the crane, thus making the process run seamlessly. The Crane was also required to travel past the building to access the stillage. A Cathead Style Bridge, with an automatic latch, was incorporated into the design.

The IAD provided a zero lift for the user. This meant 25 kilograms could be moved with only 20 grams of effort. The speed ranged from 0-35 metres per minute. This system was also implemented across several sites in Australia, making it a great success for Materials Handling Pty Ltd.